Things to consider when selecting fabrics for T-Shirt Printing

Wiki Article

From Design to Delivery: Grasping the Art of T-Shirt Screen Printing

The trip from design to shipment in t-shirt screen printing includes a collection of critical points that require interest to detail and tactical planning. It begins with comprehending the nuances of your target market, complied with by the option of appropriate materials and the prep work of artwork that satisfies high requirements. As the procedure unfolds, obstacles in top quality control and logistics can develop, possibly affecting the last end result. Discovering these intricacies exposes not only the ins and outs of screen printing yet also the vital methods that can raise a brand's standing in an open market.Comprehending T-Shirt Screen Printing

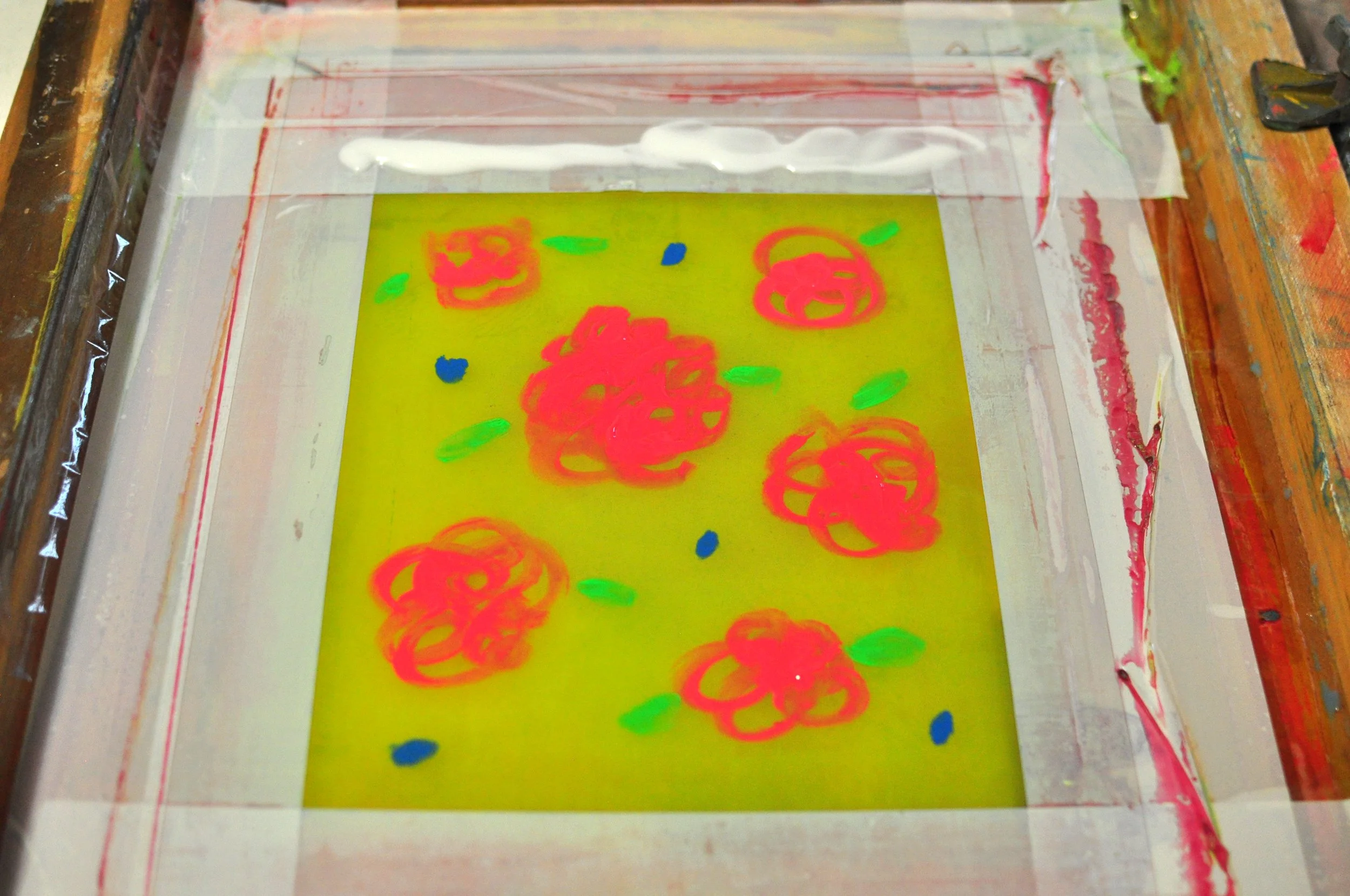

Comprehending T-Shirt screen printing involves identifying a flexible and widely made use of approach for transferring designs onto fabric. This technique makes use of a mesh and a stencil screen to apply ink onto various fabric products, generally cotton and polyester blends. The process begins with the production of a display that features the desired design, which is then meticulously aligned on the fabric.Ink is pressed with the screen's open locations using a squeegee, enabling precise application of color. This technique is preferred for its capacity to produce lively, lasting prints that hold up well to cleaning and wear. Additionally, screen printing is qualified of fitting both easy and complex styles, making it a recommended option for customized apparel, promotional items, and even creative jobs.

Additionally, screen printing supplies scalability, making it appropriate for both little set orders and large manufacturings. While first configuration prices might be greater compared to other printing techniques, the effectiveness and resilience of screen printing frequently justify the financial investment. On the whole, recognizing the basics of T-shirt screen printing is crucial for anyone looking to involve in this preferred type of material decoration, whether for commercial ventures or individual tasks.

Conceiving Your Layout

Conceptualizing your layout is an essential action in the T-shirt screen printing process, as it sets the foundation for the whole job (T-Shirt Printing). This stage entails creating ideas that reverberate with your target audience while guaranteeing that the style lines up with the brand name's identity and message. It is necessary to begin by checking out motifs, color pattern, and graphics that mirror the intended visualMapping out initial ideas can be beneficial, enabling an aesthetic depiction of concepts prior to completing the design. Consider using typography, images, and format in a method that records focus and connects successfully. On top of that, it is important to expect the printing method that will certainly be employed, as this can affect style complexity and color selections.

Participating in brainstorming sessions with team participants or looking for comments from potential clients can likewise improve the concept procedure, giving diverse perspectives that improve the style. Eventually, a well-balanced layout not only improves the aesthetic appeal of the Tee shirts yet likewise promotes a link with the audience, driving rate of interest and possible sales. Devoting time to conceive your layout can lead to a successful screen printing end result.

Selecting the Right Products

The weight of the material, usually determined in grams per square meter (GSM), influences the drape and total feeling of the Tee shirts. Much heavier fabrics might give a much more premium look, while lighter choices fit for casual wear. Texture additionally contributes; smoother fabrics tend to generate sharper prints, while textured surface areas can produce unique visual results.

Furthermore, consider the ecological effect of materials. Organic cotton and recycled polyester are gaining popularity amongst eco-conscious customers. Eventually, picking the best products entails stabilizing aesthetic allure, functionality, and sustainability, ensuring that the Tees not only looks fantastic but likewise satisfies the expectations of your target audience.

Preparing Art Work for Printing

Preparing art work for T-shirt screen printing calls for careful attention to detail to guarantee that the final print accurately reflects the intended style. The first step is to produce a high-resolution electronic documents, preferably in vector style, as this enables scalability without loss of quality. Common software utilized for this purpose includes Adobe Illustrator and CorelDRAW.Next, validate that all message is converted to lays out or rasterized to avoid font issues during printing (Abilene T-Shirt Screen Printing Company). In addition, it is crucial to validate that the color mode is set to CMYK, as this lines up with the printing process. Pay close interest to shade matching; making use of Pantone colors can help accomplish uniformity throughout various prints

Think about the measurements of the print location and keep correct margins to stay clear of style cutoff. It's likewise important to consist of registration marks for positioning throughout the printing procedure. Screen Printing. Lastly, request a proof from the printer to picture the last item before mass production. This step is essential for identifying any type of prospective concerns, assuring that the published Tee shirts meets the wanted high quality and layout requirements. Proper preparation of art work substantially affects the overall success of the screen printing task

Mastering the Printing Process

Understanding the printing process is important for achieving high-quality cause Tees screen printing. This phase involves a number of significant actions that straight influence the end product. The very first step is establishing the printing machine accurately. Correct registration of screens warranties that colors align appropriately, avoiding misprints and ensuring a professional look.

Next, choosing the right ink is necessary. Different ink types, such as plastisol or water-based, deal various surfaces and toughness. Comprehending the fabric make-up of the Tee shirts also aids in picking compatible inks.

When it comes to the actual printing, controlling the squeegee stress and angle is vital. Consistent pressure will generate also ink distribution, while the angle influences the circulation and insurance coverage. Furthermore, readjusting the rate of the printing press can influence the ink's treating process, which is essential for guaranteeing longevity.

High Quality Control and Finishing

After the printing process is complete, carrying out reliable high quality control steps ends up being important to confirm that each Tees meets the wanted criteria. Quality control entails an organized strategy to examining each garment for defects, verifying that the print top quality, color precision, and textile honesty straighten with the requirements set during the design phase.

The very first step in quality control is a comprehensive visual inspection. This requires checking for common concerns such as misalignment, ink smudges, or fading. Any type of Tee shirts that does not fulfill the top quality criteria need to be resolved without delay, either through reprinting or repair.

In addition to visual checks, it is necessary to perform clean examinations on a sample of published t-shirts to evaluate the durability read this post here of the inks and the overall longevity of the design. These tests assist confirm that the print will preserve its vibrancy and stability after multiple laundries, a vital aspect for customer complete satisfaction.

Finishing touches, such as thread cutting and the application of care labels, additionally play a substantial function in quality control - Business Branding Services. By concentrating on these facets, companies can boost the overall discussion of their products, inevitably leading to a much more enjoyable client experience

Packaging and Distribution Solutions

To achieve perfect packaging, take into consideration making use of environmentally friendly materials that line up with sustainability patterns, such as recyclable poly bags or naturally degradable boxes. Each Tee shirts need to be neatly folded and put in protective wrapping to avoid creasing and potential damages during transportation. Including a branded insert or treatment directions can further customize the experience, fostering consumer loyalty.

Picking a reputable delivery partner is important when it comes to delivery. Evaluate alternatives based upon cost, speed, and monitoring abilities. Using numerous shipping approaches can cater to various client demands, from common to expedited delivery.

Frequently Asked Concerns

What Are the Usual Errors Novices Make in Screen Printing?

Usual mistakes newbies make in screen printing consist of inappropriate screen preparation, insufficient ink blending, wrong exposure times, not enough treating, and neglecting to evaluate prints. These errors can lead to low quality and unsuitable lead to last items.Exactly How Can I Stop Ink From Blood Loss During Printing?

To stop ink blood loss during printing, assurance proper screen tension, usage appropriate solution density, pick the appropriate ink uniformity, maintain perfect curing temperatures, and prevent overwhelming the screen with excessive ink during application.What Sorts of Inks Are Best for Different Fabrics?

Picking inks based on fabric type is important. Water-based inks are perfect for cotton, offering softness. Plastisol inks fit artificial fabrics, offering durability. Discharge inks properly blend with natural fibers, making certain dynamic colors without endangering fabric stability.Exactly how Do I Pick the Right Screen Mesh Matter?

Choosing the best screen mesh matter relies on the wanted print information and ink kind. Abilene T-Shirt Screen Printing Company. Higher mesh matters produce better information, while lower matters promote thicker inks. Analyze textile kind and design complexity for excellent outcomesCan I Make Use Of Screen Printing for Tiny Batch Orders?

Yes, screen printing can be efficiently utilized for tiny set orders. This method enables detailed styles and top notch outcomes, making it a viable option for custom apparel, promotional items, or restricted edition runs.Comprehending T-Shirt screen printing includes acknowledging a flexible and commonly made use of method for moving designs onto material. While initial configuration prices might be higher contrasted to various other printing methods, the effectiveness and longevity of screen printing typically validate the financial investment. Preparing artwork for Tees screen printing needs mindful attention to information to ensure that the last print accurately mirrors the intended style. Understanding the printing procedure is necessary for attaining premium outcomes in T-shirt screen printing. Typical blunders newbies make in screen printing include inappropriate screen preparation, insufficient ink blending, inaccurate direct exposure times, inadequate healing, and ignoring to check prints.

Report this wiki page